Existing System Upgrade:

||

OVERVIEW

OVERVIEW

The existing Control System for the Line was removed and replaced with a new PLC based control system with the existing DC motors being controlled by new DC drive units on a Profi-bus network from the PLC.

The new HMI displayed all the drive's information together with the extruders and ancillary equipment.

The heating and cooling of the 2 Extruders was carried out in the PLC.

Automatic change-over of coils “on the fly” was also a feature with batched lengths being controlled through the HMI/PLC typically 9000m of cable per coiler, with the change-over taking place automatically without stopping the extruders.

Tension control was also a feature to maintain the correct tension throughout the machine to the coilers. The installation was carried out over a summer shutdown.

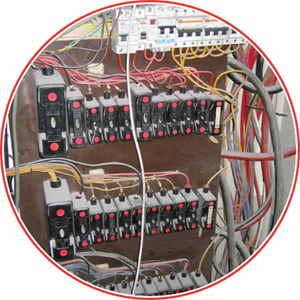

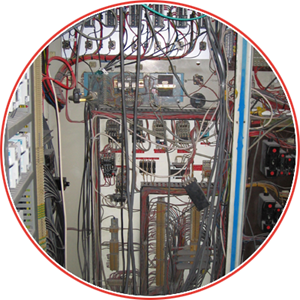

![]()

Old Control Panel

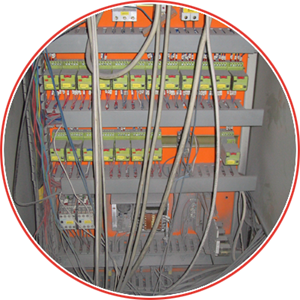

![]()

New Control Panel